Have you ever been pre-occupied and taken a bite out of something, only to get a mouthful of plastic wrap or paper lining? Well in the future, that bite could be as edible and maybe as delicious as the food itself!

The world currently uses and throws away tons of plastic every day, for example, the US alone creates more than 32 million tons of plastic waste per year. The vast majority of these plastics are neither biodegradable nor renewable. The term biodegradable means that over time, bacteria or other living organisms can break the object down into components that can be used again by other living things. Since plastics are not biodegradable, once you throw away your plastic bag or cling wrap, it will take up space in a landfill or the ocean forever, and the resources put into making that plastic will have been wasted. Modern plastics are also mostly petroleum-based, meaning they come from fossil fuels. Fossil fuels, such as oil and coal, are non-renewable due to the long time they take to form. Thus they will run out eventually – known reserves of petroleum are predicted to run out in 50 years, though more reserves will be found with improving detection technology, making the exact date hard to predict. In recent years, there has been research into developing biodegradable plastics and renewable plastics, but people have yet to create a plastic that is renewable, highly biodegradable, and is also suitable for large-scale use.

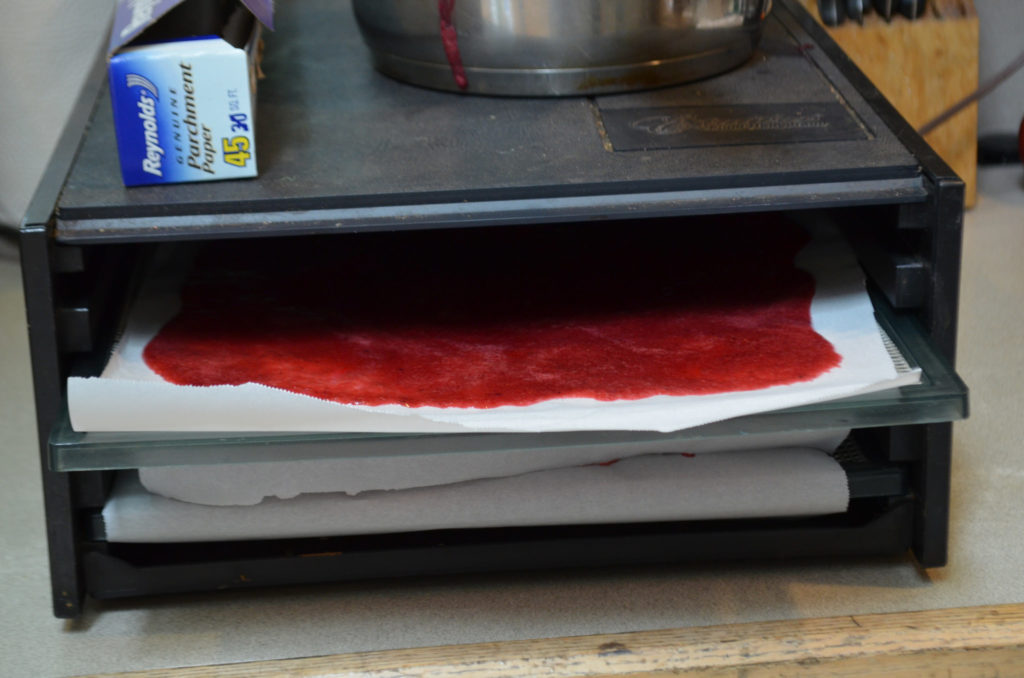

In order to make a plastic that is renewable and biodegrades quickly, researchers have turned to biological compounds, including a variety of plant and animal products. These products of interest include fruit and vegetable purees, gelatin, and even chitin, a material extracted from the exoskeleton of insects. These compounds can be used to form either coatings or films, and they are currently being tested for their usefulness in food packaging. Films made from fruits and vegetables are similar to fruit leathers, except thinner and stronger.

Food is consumed quickly and often, so using plastics that last essentially forever to preserve food for a short time (like the cling wrap around a steak) leads to a large amount of waste. The main compounds in fruits and vegetables that make for good films are pectin, cellulose, and alginate (from algae), which are all fibers and can create a strong lattice by interlocking. Researchers have also experimented with adding essential oils to the film, like oregano, citrus, and cinnamon oil, which can impede bacterial growth. However, these can change the taste and smell of the product at the concentrations needed to effectively stop the bacteria. These oils could be very useful in packaging like cooking bags, where the film around the food melts while cooking and adds flavor. Some purees and oils are also high in antioxidants, depending on the plant they are made from, and using films that are rich in antioxidants been shown to increase the shelf-life of many foods including organic leafy greens, chicken breasts, strawberries, ham, and bologna.

The main shortcomings of edible films made from fruit and vegetable purees are that they have high water solubility and permeability, and they lack flexibility and strength compared to modern plastics. The high water solubility means that they dissolve easily in water, so they can’t be out in the rain. Too high water permeability means the films let in too much water, which can make fresh food rot more quickly. The flexibility and strength of edible films have been increasing steadily as researchers experiment with inserting different nanoparticles (particles that are so small that they fit in between the plant fibers) into the films. The most common type of nanoparticles researched are plasticizers, which increase flexibility. These particles are limited to anything deemed “safe to eat” by the FDA, and there is still high potential for improvement, even with limited nanoparticle options. Water permeability doesn’t matter as much for foods high in lipids, like soybean and palm oil, which showed prolonged shelf life when stored in edible films that had active components, like antioxidants and/or essential oils. Also, researchers have been able to decrease the water permeability by adding lipids (oils or fats) to the film, though plastics from petroleum are still superior in their ability to keep water out or in.

Edible films have a bright future due to their many advantages over regular plastics – they are sustainable, highly biodegradable, and can be made from cheap ingredients, like byproducts from the food processing industry. The strength and utility of edible films will only improve over time, so it will hopefully be soon that we can have our shelf-stable fruit and meat and eat the whole thing too!